The Northbridge Makerspace has been busy in the first few weeks of school as we reopened to students As our school community knows, all Northbridge International School Cambodia staff and students are required to wear masks at all times to prevent transmission of the virus. This presents challenges for classrooms, as it can be very difficult for students, particularly non-native English speakers to understand communication when the speaker's voice is muffled and their facial expressions are hidden. The NISC Makers Club, with the help of Mr Jack, have been manufacturing clear face shields to help solve this problem.

As our school community knows, all Northbridge International School Cambodia staff and students are required to wear masks at all times to prevent transmission of the virus. This presents challenges for classrooms, as it can be very difficult for students, particularly non-native English speakers to understand communication when the speaker's voice is muffled and their facial expressions are hidden. The NISC Makers Club, with the help of Mr Jack, have been manufacturing clear face shields to help solve this problem.

Across the world, Makerspace have been responding to shortages in PPE by creating inventive solutions to quickly manufacture PPE. The NISC Makers club were in contact with a Swedish maker collective, 3DVerkstan, who have designed a simple 3D printed face shield that has been approved for clinical use by the US National Institute of Health. We requested the 3D models and files and with a few modifications to suit our equipment and materials, we were able to quickly start producing the visors on campus using our 3D printers in the Makerspace and Design Labs.

Mr James, a secondary English teacher at NISC, notes that the use of a clear face shield “offers more effective communication because it allows access to lip reading and other facial cues” facilitating “better comprehension and language learning”.

Mr Sam, a learning support specialist at NISC, also stresses the importance of being able to see the face and mouth when learning English. “Especially for our SEN learners and our lower level English speakers, they need to be able to see the mouth shape in order to understand how to properly articulate the correct sounds and pronunciation.”

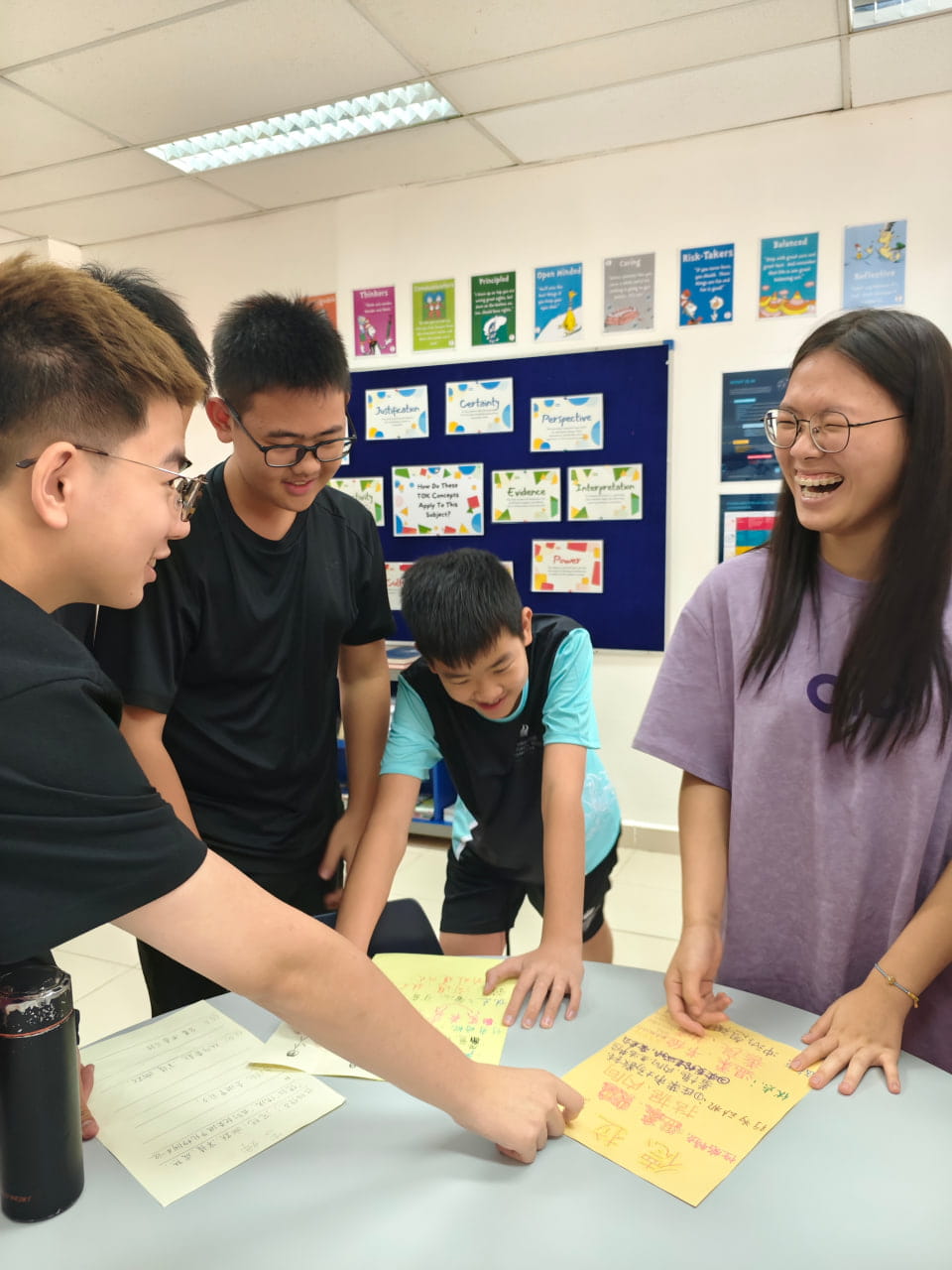

Poryi, student leader of The Makers CAS club, who helped to produce over a hundred face shields from home during the holidays says that the face shield design is particularly effective because it uses simple materials that are easy to source. They are easy to produce quickly in an emergency situation, especially when many other PPE supplies have been in shortfall during the pandemic.

Jinseng, in Grade 10, was also able to contribute, by offering to use his own 3D printer from home to create additional parts to help meet demand.

In total we have now produced over 100 face shields for all teachers, TAs, security guards, nurses and other school staff. Our student-led Maker club are now working on additional designs for other PPE-related products that could be useful for our school. The project really highlights the ingenuity and proactive nature of our school Maker community.